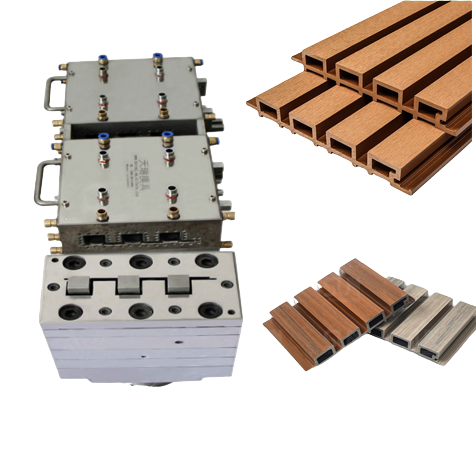

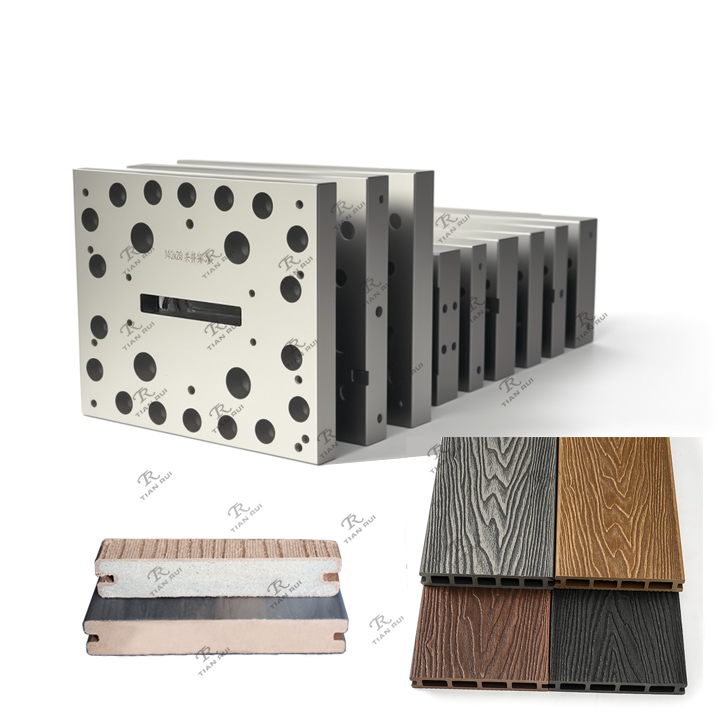

The Rapid Moulding Technology Of Plastic Profile Extrusion Mould

2017-07-14

With the rapid development and standardized of plastic profile industry,much more competitive market,Forcing profile production plant try their best to reduce production costs, improve product quality and enhance market competitiveness of products:such as choosing to buy high speed extruder,increasing production per unit of time;choosing more reasonable formula system,reducing raw materials cost;taking orders for production,reducing inventory, reducing capital occupation and so on. One essential part during the general plastic profile production

is the the mould’s disassembly and replacement, especially in the situation that having various profile section profiles. Usually,a plastic profile plant will have dozens of sets, hundreds or even thousands of sets of moulds. However,these mould could’t match the extruder one by one,result in the frequent replacement of the mould during the production process. Replacing the mould takes in time and reduce the production time,decrease the production efficiency.In response to this new situation ,As a mould manufacturer ,TianRui research and develop rapid moulding technology of the extrusion mould.

The concept of quick moulding technology including some aspects:quick mould change,quick traction,quick clean,quick maintenance ,quick produce.whether having quick moulding technology has been one of the most important symbols in mould manufacture enterprise technology progress.

Quick mould change in plastic profile production

What the quick mould change means is finishing the connection and disassembly between mould die head and the extruder host in shortest time, and the connection,fixing,adjusting,connecting water pipe joints or disassembly between calibrator system and calibrator table ,trying not to occupy the effective production time.quick mould change not only need to consider the device construction design but also need to consider the mould construction design,moreover the mould construction design and standardization are also need improved.

According to the feature of the plastic profile extrusion mould, the idea of the TianRui quick mould change is: a.no or little use the connection way of screw connection ;b.reduce the quantity of water air pipe connection between mould and device;c.use the way of automatically positioning. Finish the disassembly of the production profile mould ,So that reduce the waiting time when the

production mould to be installed heated, decrease the extruder waiting time,Improve production efficiency in the extruder and reducing the operator’s labor intensity .

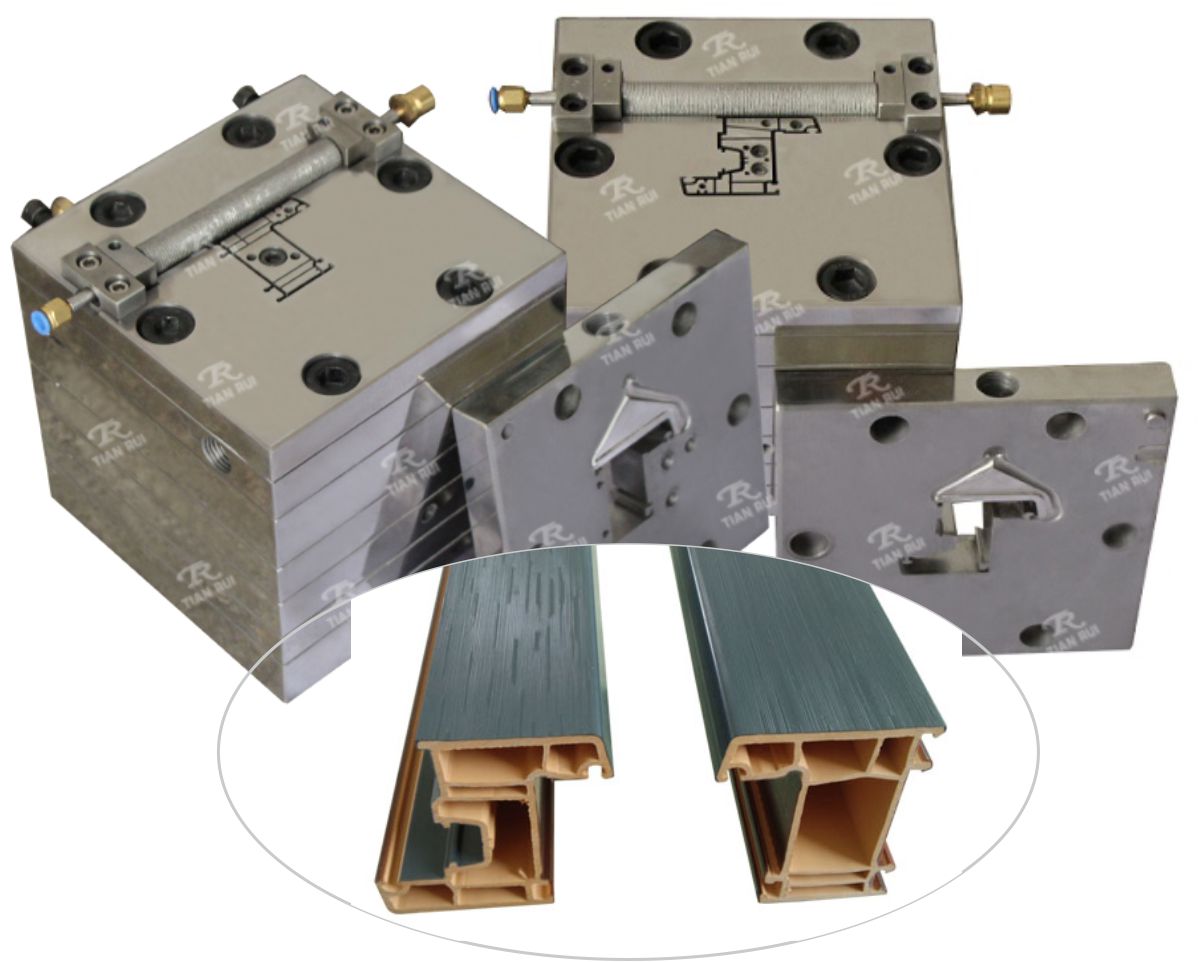

Mould die head’s quick change

The extrusion mould die head changing time is that during the production mould stop producing to prepared mould complete installation and begin to heat. This process plays a vital role to whether can realize the quick mould change.

1.stop heating ,add cleaning materials ready to power off,shut down water and vacuum;

2.Temperature measurement system, the dissolution of the heating plate;

3.relax mould die board and tighten the screws

4.remove the Flange tighten screw and the former production mould.

5clean the former production mould die

6.wait the prepared production mould connecting the Flange connection screw and install the mould die to the extruder.

7.use horizontal rule to find the level and tight the Flange connection screw.

8.Install heating plate, installed temperature measurement system, heat.

Above are the processes of extrusion mould die’s disassembly. Among them the connection and adjusting between mould die and extruder are the key point,which directly affect the mould changing time. Extrusion mould die and extruder connection mode including:Flange connection, Hough-type connection, hinged connection( as figure 1).the connection mode is depended on the production plant ’s extruder construction,the mould die need to adjust. So taking which quick connection mode need the extruder manufacturer to communicate with the mould manufacturer.

Flange connection

(a)Huff joins

(c)Hinged connection Figure 1 extrusion die and extruder connection, fast replacing of the cooling shaping system

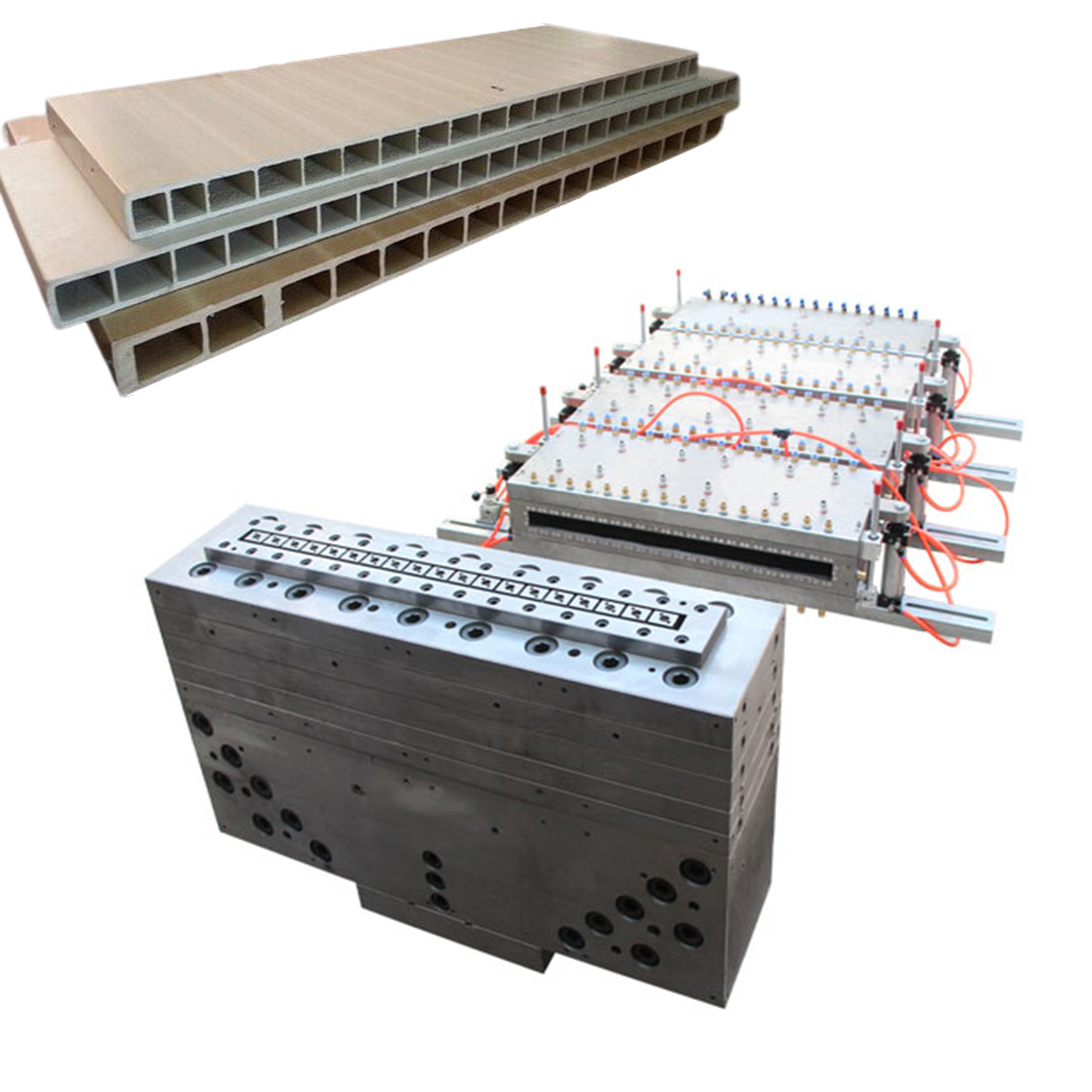

The mould changing of the plastic profile extrusion mould cooling shaping system could be carried out in the time of using extrusion die heating. So in theory,there is no contribution to the improvement of the etruder’s effective production time. However TianRui quick mould change of the cooling shaping system can reduce the mould disassembly time,simplify the operation,reduce the labor intensity of the operator, improve labor productivity.

Usually,the removal and installion of extrusion mould cooling shaping system need through the following steps:

Open cooling setting system pipes, tube fittings

a.Open the various part of shaping system and the tightening screw in calibrator table

b.Hang away the shaping system from calibrator table,suspend the prepared shaping system on the calibrator table.

c.Adjust calibrator entrance surface and mould die entrance surface to the level position.

d.Adjust positioning of shaping system and extrusion center,tighten all parts of the shaping system and the screw of calibrator table.

e.Join the inlet and outlet water pipe,extraction pipe,complete the whole installation of shaping system.

Above is a relatively complete shaping system disassembly procedure.The adjustment ,tighten of shaping system and the connection of water air pipe joint is the key point, which would determine the mould changing time of calibrator system.

1.Adjust and tighten

The adjustment of shaping system on the calibrator table ,including the consistency adjustment of extrusion center,the level adjustment of calibrator entrance surface and mould die exit surface these two aspects.The bottom board of the shaping system is a whole board,the adjustment of extrusion center has been finished in mould making process,no need this process. The shaping system that include dry shaping and wet shaping have the problem of dry wet shaping extrusion center,could

install automatic positioning mechanism on the shaping bottom board to realize the automatic alignment of extrusion center and no need manual adjustment(Figure 2).

Figure 2 Calibrator automatically pair with tank

Plastic profile is a consequent production and a vacuum suction friction shape. The parison in mold cavity connect closely with the mold cavity under the condition of vacuum suction, overcome the friction caused by vacuum suction through extruder’s traction.which would require the shaping system attach closely to the extruder’s calibrator table to prevent the traction caused longitudinal movement of shaping system on calibrator table. Tighten shaping system has two purposes:

Figure 3 calibrator connect with the non-screw shaping table

Figure 4 calibrator connect with the water tank fix tighten

TianRui The water air pipe fitting in the shaping system usually use the form of quick changing fitting.So reducing the amount of pipe fitting is the key point to the reducing of water air pipe fitting connection.Centralized water supply and Centralized vacuum is the basis for rapid disassembly of the water pipe fittings.centralized water is each dry calibrator is water supplied

By one water pipe or the whole dry calibrator is water supplied by one water pipe. Since dry calibrator has more cooling water holes,to make the cooling water in every hole flow uniform,the water pressure of the centralized water supply pipe must large enough to make every cooling water pipe have same flow,cool uniform.Centralized vacuum is each dry calibrator only use one vacuum pipe ,generally using the Inner diameter Ф30 ~ Ф50mm plastic tube to directly connect with vacuum pump,on the one hand can reduce the connection of vacuum pipe fitting,on the other hand can reduce the loss of vacuum,ensure the vacuum degree which the dry calibrator required.

The quick traction of plastic extrusion profile

Figure 5 vent design on the profile core

Exactly speaking, producing qualified products and achieve stable production in the shortest possible time plays an important role on improving profiles’yelid.

Generally ,On the circumstance of free or man-made,profile inside air and outside air is isolated when profiles(refers to the empty cavity profiles) begin to tract.It couldn’t vacuum shaping in such state.TianRui plastic mould usually pierce through when the profiles are about to exit,ensure the profile closely connect to the calibrator cavity surface under the circumstance of calibrator vacuum adsorption.To achieve the purpose of cooling shape. The profile can quickly connect to profile cavity surface,If pass the compressed air through the profile interior in the early traction ,then profiles can be quickly forced to fit with the cavity surface, thereby improving the speed of the molding profiles and improve yield. This requires the mold core part designing vent (shown in Figure 5)to facilitate pass into the air.

Otherwise TianRui’s quick connect between calibrator and die ,convenient and flexible operation in traction (user-friendly design) and so on are all facilitate to reduce the profile stable production time, improve the efficiency of the traction profiles.

Figure 5 vent design on the profile core

Plastic profile extrusion mould fast maintenance

(Including quick clean up)

The extrusion die fast maintenance or quick clean up means the mould cleaning up and maintenance work after the production in most shortest time,to make convenience for the next use.

The cleaning of mould die mainly focus on the material clean -up after production and maintenance,which require each mould plate can be easily separated and ensure the accuracy of

Repositioning. When design the cavity flow channel,TianRui consider the stability of material flow and uniformity of material outlet,also consider the convenience of material clean-up,at the same time note the possibility of scratching bump during operation(such as mould plate peripheral chamfer of 2 × 45 °).

Calibrator clean-up including:cavity surface, cooling water flow channel,vacuum air channel these three aspects. Generally cavity surface use around 1000 metallographic sandpaper to polish,clean the water logging and possibility tiny scratch. Since the cooling water existing the impurities which would deposit and attach the cooling water holes during the production procession,then make the water flow not smooth gradually,effect of cooling efficiency.so it is necessary to clean up the water holes regularly.TianRui’s design avoid the clean-up dead angel.

Since the profile formula have paraffin and other additives,the moulding would have a small amount of precipitate under the action of vacuum suction,then these precipitate would block the vacuum hole after long time. So the vacuum slot and hole need to clean up after long time to avoid the existence of vacuum salt dead angel and improve the cleaning efficiency.

Another noteworthy question is, When traction process occurs profiles stuck should Should be able to quickly remove the jammed profiles, clean the calibrator and water tank in the shortest possible time to re-enter the normal production.

Rapid extrusion of plastic profile

Under the premise of making profile quality, High-speed continuous production is the hope of every manufacturer ,but quick produce is a system problem. Involved the aspects including:raw material formulation, extruders of effective, die cavity flow channel design, calibrator and water tank design, calibrator equipment cooling and vacuum capability. Shaping system (calibrator, vacuum tank) efficient cooling capacity is a key factor. Firstly ,to ensure good vacuum adsorption capacity, ensure good connect with the calibrator can greatly play the cooling efficiency of calibrator.

Conclusion

Quick mould technology change can reduce the labor intensity of workers, increase the effective production time of the extruder, TianRui mainly includes the following aspects:

1. Mould changing carry out as much as possible under the machine, reduce the operation time on machine.

2.The fasten of shaping system on calibrator table and various parts of the system use the non-screw connection structure.

3.Using centralized water supply structure and centralized vacuum structure, reduce the amount of water air pipe fitting,simplify the connection of water air pipe fitting.

4.Structural design to be as reasonable as possible to facilitate the quick clean up of mold.

5.Improve the design program of the mould to suit for customers’ formulation and equipment.

E-mail :

E-mail :

E-mail:

E-mail:

_200x150.jpg)